Our expertise and excellence: Sheet Metal Forming

- Aug 2, 2023

- 3 min read

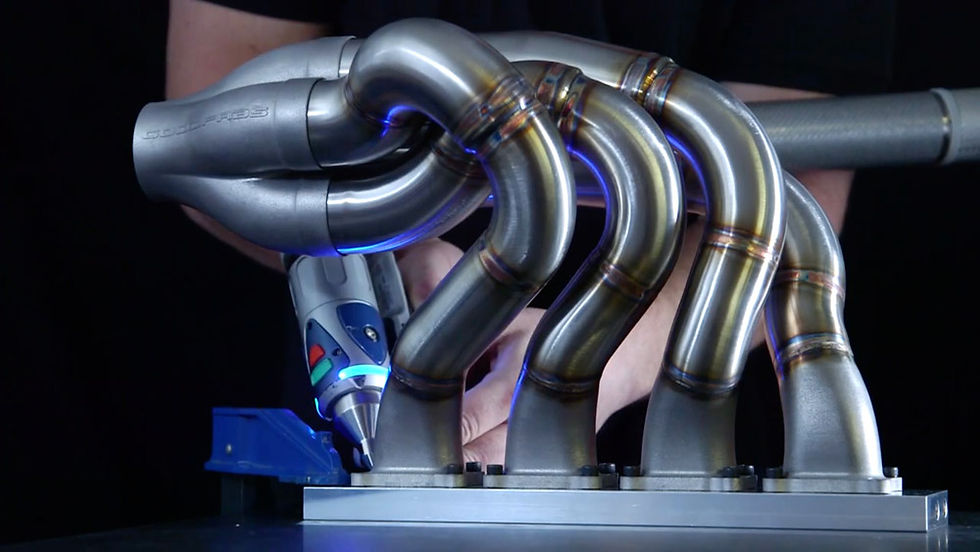

Sheet metal forming is a versatile and crucial process in modern manufacturing, transforming flat sheets of various metals into complex and functional components used in a wide range of industries. It encompasses various techniques, including bending, stretching, deep drawing, and more. Goodfabs Performance Engineering, a leading company based in the UK, specializes in sheet metal forming with a proven track record of excellence and expertise. If you're seeking top-tier solutions for your sheet metal requirements, here's why Goodfabs Performance Engineering should be your first choice.

Unparalleled Expertise: Goodfabs Performance Engineering boasts a team of highly skilled engineers and technicians with extensive experience in sheet metal forming. Our experts have an in-depth understanding of material behavior, tooling design, and process optimization for a variety of metals including aluminium, stainless steel, inconel, and titanium. With their expertise, we can tackle even the most intricate design challenges and deliver precision-formed components that meet your exact specifications.

Cutting-Edge Technology:

At Goodfabs Performance Engineering, we invest in state-of-the-art technology to ensure superior results with a wide range of sheet metal materials. From aluminium to stainless steel, inconel 625, and titanium, our advanced machinery and equipment, including press brakes and hydraulic presses, offer consistent, high-quality forming that minimizes defects and maximizes efficiency.

Customized Solutions: No two projects are the same, and that's where Goodfabs Performance Engineering truly shines. We understand that each customer has unique requirements and design considerations for different metals. Our team collaborates closely with you to develop tailored solutions that perfectly align with your needs. Whether it's a single prototype or a large-scale production run in aluminium, stainless steel, inconel 625, or titanium, we deliver excellence every time.

Design for Manufacturability: Goodfabs Performance Engineering goes beyond just producing parts; we offer design for manufacturability (DFM) services. Our experts analyze your designs to identify potential challenges and opportunities for optimization with a variety of metals. By optimizing your designs for efficient manufacturing, we help you reduce costs, minimize waste, and accelerate time-to-market.

Quality Assurance:

Quality is at the heart of everything we do. Our commitment to delivering flawless components is reflected in our stringent quality control processes. Goodfabs Performance Engineering adheres to industry-leading standards and certifications, ensuring that every product leaving our facility in aluminium, stainless steel, inconel 625, or titanium meets the highest quality benchmarks.

Cost-Efficiency: Sheet metal forming is a cost-effective manufacturing method, and Goodfabs Performance Engineering takes it a step further. By leveraging our expertise, technology, and efficient processes, we provide competitive pricing without compromising on quality for various metals. We optimize material usage and minimize production time to offer you the best value for your investment.

End-to-End Services: Goodfabs Performance Engineering offers comprehensive end-to-end services, covering every aspect of sheet metal forming with a wide range of metals. From initial design and prototyping to production and finishing in aluminium, stainless steel, inconel 625, or titanium, we're your one-stop solution. Our capabilities include laser cutting, CNC punching, welding, assembly, and more, ensuring a seamless and streamlined experience from start to finish.

Reliability and Timely Delivery: We understand the importance of meeting deadlines. Goodfabs Performance Engineering is renowned for its reliability and on-time delivery. Our well-organized production processes and project management expertise allow us to consistently deliver within agreed-upon timelines, helping you stay on schedule and achieve your project goals.

Proven Track Record: Goodfabs Performance Engineering has a proven track record of successfully serving diverse industries, including racing, automotive, aerospace, battery development and more, with various metals such as aluminium, stainless steel, inconel 625, and titanium. Our portfolio showcases a wide array of projects that highlight our ability to handle complex geometries, tight tolerances, and different material types. We're not just a supplier; we're a partner you can trust.

In conclusion, Goodfabs Performance Engineering stands as a beacon of expertise, innovation, and quality in the realm of sheet metal forming with a variety of metals. With a team of seasoned professionals, cutting-edge technology, and a commitment to excellence, we are well-equipped to address your sheet metal requirements in aluminium, stainless steel, inconel 625, or titanium with precision and care. When you choose Goodfabs Performance Engineering, you're not just choosing a supplier – you're choosing a partner dedicated to turning your visions into reality.

Contact us today to discuss how we can elevate your sheet metal projects with various metals to new heights.

Comments