CMM INSPECTION

CMM Inspection

Central to our inspection process is the Faro Edge arm which is a coordinate measuring machine (CMM) allowing us to measure in multiple planes with maximum flexibility using both probes and laser scanning attachments.

Bespoke software allows us to create reports showing how finished welded parts relate to original CAD models.

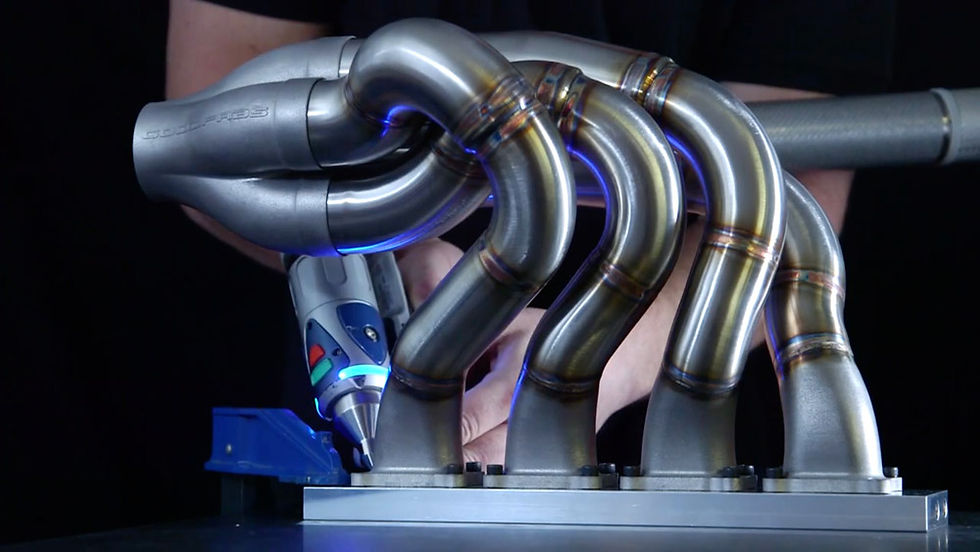

Inspecting an exhaust system using the Faro arm with a laser attachment at GoodFabs

The machined or laser-cut parts and fixtures made by sub-contractors or in the GoodFabs in-house machining department go through a specific GoodFabs inspection process to ensure the quality and a smooth flow of checked parts to the fabrication teams.

Customers work closely with the inspection department and regularly visit to discuss their specific requirements and techniques to ensure that any exhaust or other fabricated parts can be accurately jigged, measured and transported at different stages of the fabrication and post-fabrication process.

All parts received by GoodFabs are checked by our inspection department before being introduced into the fabrication process and all parts leaving GoodFabs for finishing are inspected before and after any processes are carried out.

Preparing the Faro Edge arm with laser attachment for inspection

Measuring an F1 exhaust manifold using the Faro Edge arm and laser attachment

Measuring DMLS parts on an exhaust manifold

Laser scanning for inspection with Faro Edge arm

Software image of laser scanned exhaust manifold to create inspection report

Measuring an inconel exhaust manifold using the Faro Edge arm and laser attachment

Measuring an F1 exhaust manifold using the Faro Edge arm and laser attachment

Laser scanning for inspection with Faro Edge arm

Inspecting an exhaust system using the Faro arm with a laser attachment