FABRICATION

Fabrication

Most of our fabrication at GoodFabs involves lightweight exotic metals which perform well in high heat environments.

Nickel alloys such as inconel are not readily available in tube form so we start the fabrication process with flat sheets of metal with a material thickness that typically ranges from 0.5mm to 1.6mm.

Large thin sheets are precision cut with a guillotine and then rolled and seam welded to form a custom-made tube.

Fabricator checking dimensions in the tube making department

This tube is then mandrel bent on one of our Clark & Lewis tube benders using a range of custom-made bend tooling that is probably the most extensive outside the aerospace industry.

A set of perfectly formed bends is then passed onto the fabricator/ welder who will have been provided with a CAD drawing, a fabrication jig and a set of laser cut and machined components which he will use to make the part or exhaust system.

Our skilled fabricators will discuss the precise order and method of manufacture with management team to ensure that the most efficient manufacturing approach is used, taking into account any other post-fabrication processes - such as heat treatment or shot peening - that may be needed either during or post-fabrication welding.

Once an exhaust part has been completed it will be passed onto our separate

inspection department where it can be CMM inspected using our FARO arm or laser scanned, taking into account the tolerances prescribed by the customer.

The part may go through an in-house NDT process using dye penetrant to confirm the quality of the welds.

Other post fabrication processes, such as shot peening or heat treatment may then be carried out before being returned for a final inspection.

Parts can be marked by laser etching and carefully packed for same day or overnight delivery.

Mobile aluminium jig trolley

Mobile aluminium jig trolley

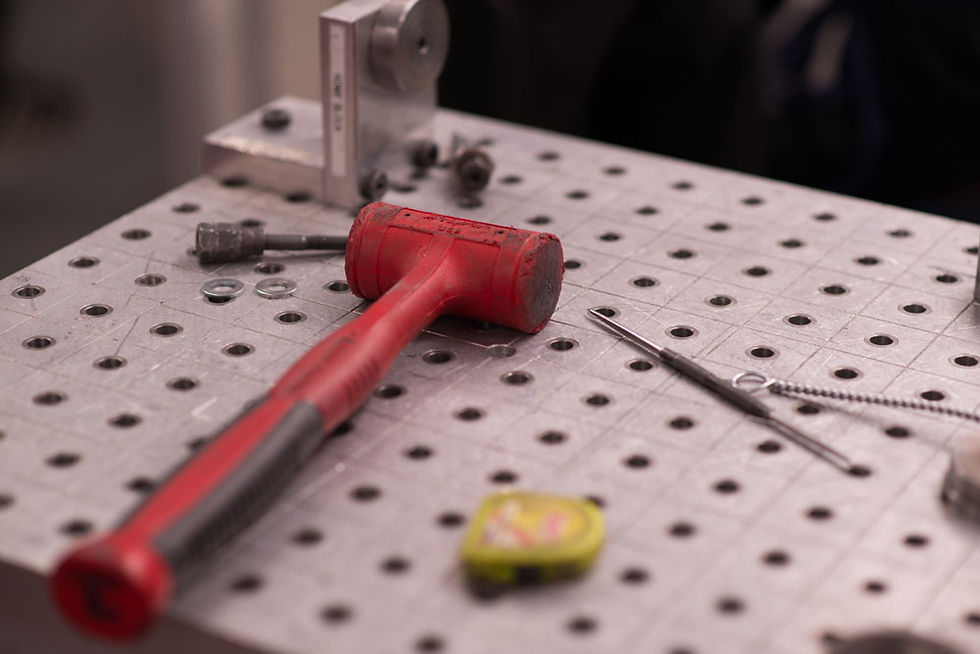

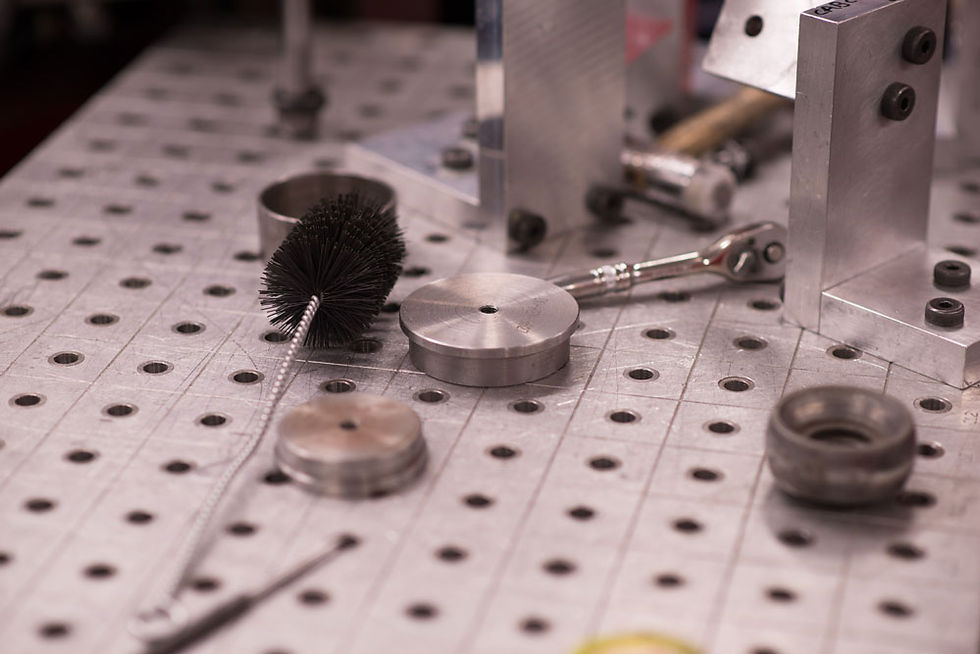

GoodFabs fabricator/ welder at workbench

GoodFabs fabricator/ welder at workbench

GoodFabs fabricator/ welder using flywheel

GoodFabs fabricator/ welder bolting up an F1 inconel exhaust system